Battery swapping is being touted as a potential solution to the problems associated with electrification of large and hard to reach off-highway machines. But does it really offer the answer to creating zero-carbon equipment such as tractors, mining machines and excavators?

These machines are some of the largest in the world, demanding huge amounts of power and generating substantial volumes of pollution. Essential to food production and major infrastructure projects, electrification of large off-highway machines offers the opportunity to dramatically reduce greenhouse gases and pollution. However, they are notoriously difficult to electrify because of their power demands and lack of access to the grid. They require large, expensive batteries and access to charging stations, which can often prove unaffordable even with the lower cost of electricity in comparison with diesel.

Battery swapping could provide one answer to problems around the electrification of off-highway machines — particularly for hard-to-electrify applications such as tractors — and it offers potential new business models for equipment hire companies and OEMs.

Off-Highway Electrification Is Happening, but Slowly

Although slower to electrify than on-highway vehicles, we are seeing emerging solutions for off-highway electrification. However, adoption rates and emissions reduction have been low, even in relatively progressive markets.

There are specific challenges in relation to hard-to-reach applications, such as agriculture, mining and construction, and very large machines. Part of this problem stems from the continuous usage of off-highway applications, which, unlike passenger cars, may be in use for eight hours or more per day. In such cases, a very large, expensive battery is required to provide the power and performance needed, making machines prohibitively expensive. Additionally, designing machines with very large batteries is a challenge and recharging takes a long time, taking the machine out of operation at a significant financial cost and adding potential delays to projects.

Battery Swapping Has a Checkered Past, but Is it Part of Our Future?

Having additional batteries that can easily be swapped in and out of vehicles enables one to charge while another is in use, considerably cutting downtime. In addition, the battery itself does not have to be so large as batteries can be swapped in and out during operation without significantly disrupting operations.

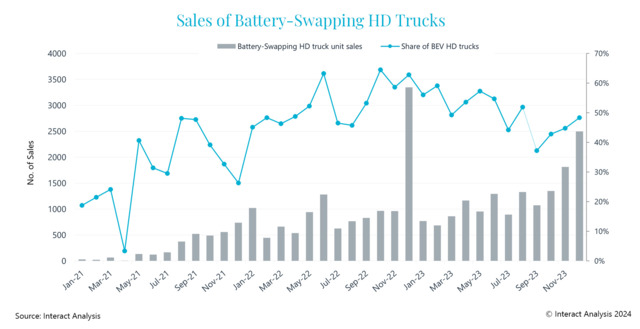

Battery swapping for electric vehicles, at least in the passenger car market, is not a new concept. Indeed, there have been numerous projects over the decades, including its use in the Electrobat electric taxicabs in New York in the 1890s. Batteries could be replaced within seconds and the taxis could be operated all day. However, the Electrobats only flourished for a few years before poorly run operations outside New York caused the model to collapse. In the 2000s, Israeli startup Better Place failed, despite its initial promise. There is now some progress being made in China, where several thousand heavy-duty trucks support battery swapping and a number of car brands are working together to create an ecosystem.

Battery-swapping heavy duty trucks are seeing some sales growthInteract Analysis

Battery-swapping heavy duty trucks are seeing some sales growthInteract Analysis

Is Anyone Experimenting With Off-Highway Battery Swapping Technology?

In the off-highway sector, we are also seeing the launch of machines that support battery swapping, such as Sandvik’s battery electric underground loader, with a battery pack that can be swapped in as little as five minutes while the operator is still in the vehicle. The PC05E-1 micro-excavator, developed jointly by Komatsu and Honda is an expanded version of the PC01E-1 and is powered by a small 1 kWh Honda Mobile Power Pack, allowing the battery to be easily exchanged by hand. Its small size and weight make it highly maneuverable and suitable for small groundworks.

Developed by the Traktorarvid Arvid Örde and RISE Research Institutes of Sweden, the Drever 120 is an autonomous tractor that features a modular battery swapping system. Furthermore, a 2020 collaboration between Webasto and Dutch company Electric Construction Equipment (E.C.E), the latter a part of Doosan distributor Staad, converted Doosan excavators to operate with modular swappable Webasto battery packs. Each excavator is fitted with two swappable ‘powerboxes’ with 140 kWh of capacity. Also utilizing 140 kWh E.C.E/Webasto swappable battery packs is a battery swapping solution for agricultural tractors developed by AGROMEC in the Netherlands that can be fitted to the front of the machines to provide a boost to its 70 kWh on-board battery and enable longer field operation. Several of these tractors are already in operation in the Netherlands.

Each of these models provides longer field operation and, although electrification of agricultural equipment is challenging, it is possible that a standardized battery swapping solution could provide the impetus needed to convince farmers of the benefits of electrified machines and drive-up adoption rates.

Offering a slightly different sustainable solution, ZQuip, a subsidiary of Moog, has developed a machine and industry-agnostic battery swap conversion solution to be retrofitted to existing diesel machines so they can run on electricity. The ZQuip energy modules can also be used at jobsites as both a zero-emission powertrain for machinery and a modular energy storage system, discharging electricity to other machinery and equipment on construction sites.

What Are the Key Benefits of Battery Swapping for Off-Highway Machines?

Given that 38% of the cost of an electrified off-highway machine is in the battery, building machines with swappable batteries enables battery packs to made smaller or even eliminated completely from the machine. This substantially drives down the upfront cost and could lead to widespread adoption as operators are able to select the number of packs required for a job, rather than purchasing a machine with a very large battery when they might rarely need all the stored energy.

The problem with machine downtime while it is charging is eliminated as batteries can be swapped within minutes. Batteries can also be used for grid storage when not in machines (both overnight or during off-seasons) to provide operators with an additional revenue stream.

In addition, the obvious benefits of battery swapping for end users and the solutions it provides to the electrification of large and hard to reach off-road applications, it also supports new business models. This opens up new opportunities and potential revenue streams for OEMs and rental and plant hire companies, which could develop a lucrative source of income from end users requiring additional capacity.

With the growing focus on sustainability and the drive to reduce greenhouse gas emissions and other pollutants, incentives for electric vehicles are increasing. Concerns about the availability of biofuels and efuels mean that low and zero-emission off-highway machines may need to become electric in order to meet strict emissions targets and comply with legislation.

For Large & Hard-to-Reach Applications, Could Battery Swapping Provide an Answer?

Deployments of electric off-highway equipment are currently relatively low and battery swapping could well be a disruptive technology both for the electric off-highway machinery sector and the wider off-highway market as a whole. In this article from June last year, I explored how electric construction equipment could alter the landscape of the construction equipment sector and battery swapping may well play a part. Although currently a nascent market, battery swapping offers the potential to push down the cost of machines and solve the problems associated with equipment being out of operation while it is charging. We wonder how long it will be before it is seen more widely in operation on farms and construction sites.