With most of the attention surrounding carbon reduction focused on battery electric vehicles (BEVs) and hydrogen electric vehicles, the current reality is these vehicles remain out of reach for many customers for a variety of reasons ranging from initial cost to availability of charging or fueling, duty cycle, etc. It is going to take a significant amount of time before these technologies may be viable for a larger percentage of customers. Customers still need to factor in key business metrics such as total cost of ownership and the bottom line when making large equipment purchases.

Electric vehicles hold promise and costs and infrastructure will continue to improve, but internal combustion engines can provide a path forward to zero emissions. There are still opportunities to significantly cut carbon emissions utilizing the internal combustion engine. “We know that our planet cannot wait for the perfect solution to happen,” says Srikanth Padmanabhan, president, engine business, Cummins. “Instead, our approach needs to be a combination of using zero emissions power where it is available and using cleaner, lower carbon power where it is not. This I call continuous improvement beats postponed perfection. Getting to zero is not a light switch event. Anything we can do to start reducing the carbon footprint today is a win for the planet.”

Solutions Tailored the Customer Situation

“Some users may be able to quickly transition to battery electric and fuel cell electric solutions that we are producing through our new power business,” says Padmanabhan. “However, for others, they just cannot transition today.” Every end user needs to evaluate the economics, power and range requirements, including refueling needs. “In addition, they have to navigate the infrastructure challenges, regional resource needs, bottom lines, total cost of ownership and the limitations of technology which make every decarbonizing challenge unique. It is complicated and there is not a one-size-fits-all solution.”

To help customers who cannot take the immediate leap to battery electric and fuel cell electric solutions, Cummins is introducing a line of agnostic internal combustion engine platforms designed to help fleets move towards zero emissions. “These unified platforms will use engine blocks and key components that share a common architecture but will be optimized for different low carbon fuel types,” says Padmanabhan. “The basic concept is that below the head gasket will have similar components. Above the head gasket will have different components for different fuel types.” Hydrogen internal combustion engines will provide a low cost zero-carbon solution for high load factor and high utilization applications where battery-electric solutions cannot meet the operational requirements and fuel cells are not yet economically viable.Cummins

Hydrogen internal combustion engines will provide a low cost zero-carbon solution for high load factor and high utilization applications where battery-electric solutions cannot meet the operational requirements and fuel cells are not yet economically viable.Cummins

Cummins is quickly ramping up these engine offerings. “We have already announced both natural gas and hydrogen powered 15-liter engines for the heavy-duty and long-haul markets,” Padmanabhan. “We will soon be offering gasoline, propane and hydrogen internal combustion engines designed for the medium-duty vocational and transit applications.”

Cummins plans on providing a complete range of solutions ranging from advanced diesel engines to battery or hydrogen electric that will address the needs of any customer. “Our current products include advanced diesel and natural gas engines,” says Jonathan White, vice president of engineering. “Over the years we’ve continued to innovate these technologies so that they are cleaner and more efficient Today, our diesel product line provides fuel economy that is over 20 percent better than 15 years ago.” And this work continues. “Our engineers are working on making internal combustion engines even more efficient by integrating components into complete powertrain solutions. These components include filtration, after treatment, turbochargers, fuel systems, electronic control systems, air handling systems, automated transmissions and telematics.”

Natural gas has been a primary focus to reduce emissions in internal combustion engines. “Our natural gas engines have reduced NOx emissions by more than 90 percent compared to today’s EPA requirement,” notes White. “When powered with renewable natural gas, they can deliver sub zero greenhouse gas emissions by delivering the same power and reliability of a diesel. Think about the impact on the planet if more trucks were powered by renewable natural gas.”

Seamlessly Transition to Reduced Emissions

The Cummins unified technology platforms will make it more seamless for fleets to begin transitioning to zero carbon emissions today. The engines will expand the portfolio of the existing B, L and X Series engine platforms. “In addition to our 15-liter natural gas and hydrogen products, we’re adding gasoline, propane and hydrogen to our B6.7 portfolio, complementing our current diesel and natural gas products,” says White. “These fuel agnostic engine platforms will feature a series of engine versions that are derived from a common base engine, which means they have a high degree of parts commonality. The bottom of the engine looks the same and the top end can accommodate different fuels. Each engine version can operate using a different single fuel.”

Many options are commercially available. “Today, you can already order natural gas versions of several Cummins engines,” says White. “These near zero emissions natural gas engines can operate on compressed or liquid natural gas. In addition to natural gas, we are designing engines that run on propane while featuring a high degree of parts commonality with our natural gas and diesel fuel engines. Finally, we plan on adding hydrogen fuel engines. Our testing of hydrogen fueled internal combustion engines is progressing well.”

The fuel agnostic approach allows end users to pick the right powertrain for their application with the lowest CO2 impact. “It doesn’t matter which fuel type a fleet selects, these new fuel agnostic platforms bring the ideal mix of reliability and reduced or zero carbon emissions to the table,” says White. “Today’s digital and connected technologies allow us to extract insights specific to different engine duty cycles and leverage these to design reliable agnostic platforms.”

Common Architecture Benefits OEMs and Service Technicians

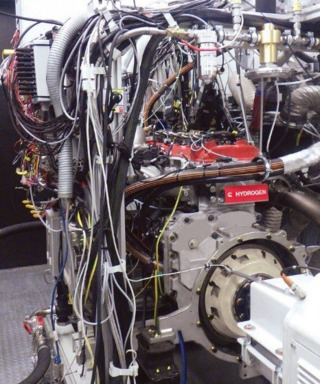

Parts commonality is a key advantage of this new technology approach. “Our engineers want to design products that reduce carbon emissions without the steep learning curve in terms of adoption,” he adds. “Whether it is built on the X, L or B Series platform, these new unified products will have 80 percent parts commonality and look and feel familiar to customers and technicians. A Cummins Hydrogen Internal Combustion Engine (ICE) undergoes testing.Cummins

A Cummins Hydrogen Internal Combustion Engine (ICE) undergoes testing.Cummins

“The product architecture, engine footprint and even service intervals are all designed around using the same parts and components where possible,” says White. “This makes these products an economically viable, scalable and eco-friendly solution for the planet that can be adopted today. They will be easy to integrate into existing truck models and deliver much lower costs associated with upskillng technicians and retail service locations.”

Geography plays a key role in which technology selection. “We know adoption curves will vary by market application, region, country, even by state and city,” he adds. “A technology that works for one application may not be the right choice for another.”

Internal combustion engines have been around a long time and the infrastructure to produce them is well established. “The upfront cost of these engines will be much lower than moving to fully electric or fuel cell options,” says Amy Boerger, vice president of North America On Highway. “That’s critical to lowering the barrier of entry for fleets looking to adopt emission reducing technologies today.”

Any time there are significant changes to a powertrain and its footprint, it can result in the OEM having to make significant investments. “These engines will also deliver increased benefits to our truck OEM partners,” says Boerger. “The architecture and footprint of these engines will be similar across the current product platforms. That will make it easier for OEMs to integrate various fuel types across the same truck chassis. This means lower costs associated with vehicle redesign and any associated production line changes. This will minimize costs for technicians and training and in retooling service locations.”